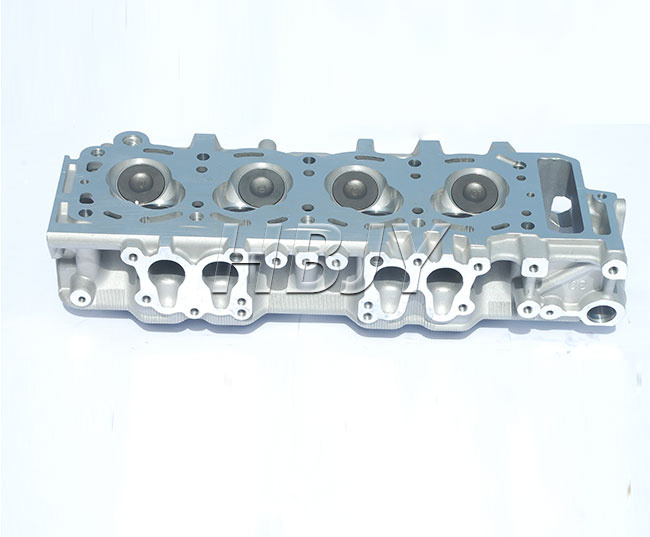

Warpage performance: The flatness error between the cylinder block and the Toyota 22R Cylinder Head exceeds the limit, which will cause the cylinder to be tightly sealed, water leakage and air leakage, resulting in insufficient compression force. In severe cases, the cylinder head gasket will be damaged.

Causes of warpage: When the diesel engine is working at high temperature, it suddenly cools; when assembling, the cylinder head bolts are not tightened according to the specified order and torque, or the tightening torque is different; the material of the cylinder head does not meet the requirements; The cylinder head will cause the bottom of the cylinder head to warp and deform.

The method for inspecting the flatness of the contact surface between the cylinder head and the cylinder block: placing the flat ruler on the plane of the cylinder head, and measuring the maximum value of the gap with a thickness gauge is the flatness of the plane.

Repair method: (1) scraping method. Clean the Ford WL WLT Cylinder Head and inspection platform before scraping. Apply a thin layer of red or red ink on the working surface of the inspection platform, gently place the cylinder head on a flat surface, make the cylinder head cover the platform and push it back and forth for 3 to 5 times. Finally, remove the cylinder head and look at the protruding part of the plane warp, then scrape the printed part with a spatula and repeat it several times until it meets the requirements. (2) Mutual research method. Applying a paste between the cylinder block and the cylinder head for direct grinding is one way to eliminate warpage. Before grinding, use cotton yarn or butter to block the water channel and bolt holes on the two planes of the cylinder block and the cylinder head to avoid falling into the abrasive. Then fix the cylinder block to the base or the wooden frame so that its plane is in a horizontal position. When grinding, first apply a layer of abrasive on the plane of the cylinder block (generally made up of valve sand and oil). Then, the cylinder head is placed flat on the cylinder block so that the cylinder head plane abuts the plane of the cylinder block, and then the cylinder head is pushed forward and backward and left and right to make the two planes grind each other. After grinding for 10-20 min, the cylinder head is removed, the old abrasive is removed, the new abrasive is applied, and the grinding is continued until there is no obvious black mark on the cylinder block and cylinder head plane.